The New Silicon Moat: How Generative AI is Revolutionizing Semiconductor Manufacturing

Introduction: Beyond the Hype, AI’s Impact on Hard Tech

The artificial intelligence landscape is in a constant state of flux, with daily headlines dominated by developments from major players. The latest Mistral AI News, alongside ongoing updates in OpenAI News and Google DeepMind News, often focuses on chatbots, content generation, and software applications. However, a far more profound and potentially disruptive shift is occurring at the intersection of AI and “hard tech”—the physical industries that build our world. A landmark strategic partnership between leaders in generative AI and semiconductor manufacturing equipment is signaling a new era where intelligent software is becoming as critical as the physical hardware it controls. This fusion promises to solve some of the most complex challenges in chip fabrication, dramatically shortening yield times, creating unprecedented competitive advantages, and reshaping the geopolitics of technology. This article explores the technical underpinnings of this revolution, from foundational concepts to advanced implementations, and examines the strategic implications for the entire technology ecosystem.

Section 1: Core Concepts – AI for Process Control and Defect Analysis

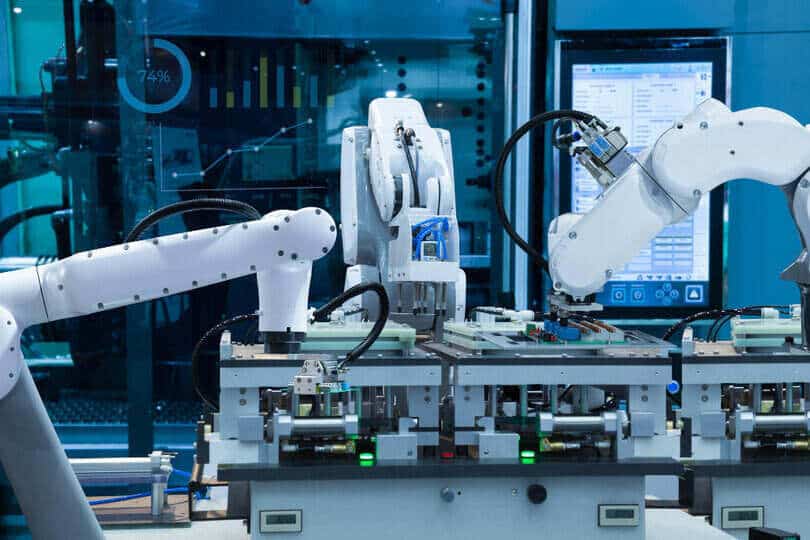

Semiconductor manufacturing is a process of staggering complexity. A modern CPU undergoes hundreds of steps, each with thousands of variables that must be controlled with atomic precision. The primary challenge is maximizing “yield”—the percentage of functional chips per silicon wafer. Even minute deviations can lead to defects, rendering chips useless and costing millions. Traditionally, engineers have relied on Statistical Process Control (SPC), but as chip features shrink to the nanometer scale, the sheer volume and complexity of data generated by fabrication equipment (fabs) overwhelm conventional methods.

This is where modern AI, particularly computer vision and multimodal models, comes into play. Fabs generate terabytes of data daily, including high-resolution wafer inspection images, sensor telemetry, and equipment logs. AI models can analyze this data to identify patterns invisible to the human eye or traditional algorithms.

From Image Recognition to Root Cause Analysis

A common task is wafer map defect classification. After fabrication, each die on a wafer is tested, and the results are plotted on a “wafer map.” Specific spatial patterns of failed dice often correspond to particular manufacturing process errors. A deep learning model, built with frameworks mentioned in recent PyTorch News or TensorFlow News, can be trained to recognize these patterns instantly.

Let’s consider a practical example using the Hugging Face Transformers News ecosystem to classify wafer defect images. We can use a pre-trained Vision Transformer (ViT) model and fine-tune it on a dataset of labeled wafer maps.

import torch

from PIL import Image

from transformers import ViTImageProcessor, ViTForImageClassification

import requests

# Load a sample wafer map image

# In a real scenario, this would come from a fab's inspection tool

url = 'https://example.com/wafer_map_defect_image.png' # Placeholder URL

try:

image = Image.open(requests.get(url, stream=True).raw)

except:

# Create a dummy image if the URL fails for this example

image = Image.new('RGB', (224, 224), color = 'red')

# --- Model Loading ---

# This leverages models available through the Hugging Face Hub

# In a real application, you would fine-tune a model on your specific defect types

model_name = 'google/vit-base-patch16-224-in21k'

processor = ViTImageProcessor.from_pretrained(model_name)

model = ViTForImageClassification.from_pretrained(model_name)

# --- Preprocessing ---

# The processor standardizes the image for the model

inputs = processor(images=image, return_tensors="pt")

# --- Inference ---

with torch.no_grad():

outputs = model(**inputs)

logits = outputs.logits

# --- Post-processing ---

# The model predicts the class with the highest probability

predicted_class_idx = logits.argmax(-1).item()

# In a real system, you would map this index to a specific defect class

# e.g., {0: 'Center', 1: 'Donut', 2: 'Edge-Loc', 3: 'Scratch', ...}

defect_classes = {

19: 'Scratch', # Example mapping from ImageNet class for illustration

933: 'Ring', # Another example

}

predicted_class = model.config.id2label.get(predicted_class_idx, "Unknown Defect")

print(f"Predicted Defect Class ID: {predicted_class_idx}")

print(f"Predicted Defect Type: {predicted_class}")

# This information would then be fed into the Manufacturing Execution System (MES)

# to flag the wafer and potentially halt the process for investigation.This simple classification is just the beginning. By correlating these visual defect patterns with time-series data from equipment sensors, AI can perform root cause analysis, pointing engineers directly to the faulty component or process parameter that needs adjustment. This capability is a game-changer, reducing diagnostic time from days to minutes.

Section 2: Implementation – Building a Multimodal AI Pipeline for Yield Prediction

A truly effective system moves beyond reactive defect detection to proactive yield prediction. This requires building a sophisticated data pipeline that integrates multiple data modalities—images, time-series sensor data, and unstructured text from engineering logs. This is where frameworks like LangChain News and LlamaIndex News are starting to find applications in industrial settings, helping to parse and structure text-based data.

The Data Pipeline Architecture

A typical pipeline for a fab would look like this:

- Data Ingestion: Raw data is collected from lithography machines, etchers, and metrology tools. This is often handled by distributed systems, and insights from Apache Spark MLlib News or Ray News are highly relevant for processing this scale of data.

- Feature Engineering: The raw data is cleaned and transformed. For sensor data, this might involve creating features like rolling averages or frequency domain transformations. For text logs, it could involve using models from Sentence Transformers News to create vector embeddings.

- Multimodal Model Training: A model is trained to predict yield based on this combined data. This often involves a neural network with separate “heads” for each data type, which are then fused into a final prediction layer. The training process is managed and tracked using MLOps tools, a space where MLflow News and Weights & Biases News are leading the way.

- Deployment and Inference: The trained model is deployed for real-time inference. For low-latency requirements, this often involves optimization using tools like NVIDIA AI News‘s TensorRT or the open standard ONNX News.

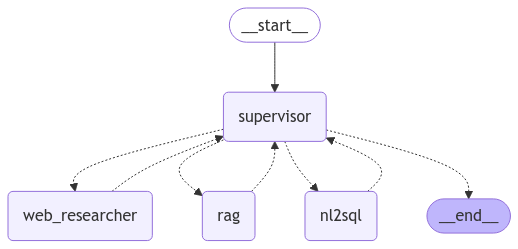

Example: A Fab Assistant with RAG

Imagine an engineer investigating a yield drop. Instead of manually sifting through thousands of log files and sensor readings, they could interact with an AI assistant. This assistant would use a Retrieval-Augmented Generation (RAG) architecture, powered by a vector database like Pinecone News or Milvus News, to find relevant information and synthesize an answer.

Here’s a conceptual Python example using LangChain to build such a system. It would query a vector store containing indexed maintenance logs and equipment manuals.

from langchain_community.vectorstores import Chroma

from langchain_community.embeddings import OllamaEmbeddings

from langchain_core.prompts import ChatPromptTemplate

from langchain_community.llms import Ollama

from langchain_core.runnables import RunnablePassthrough

from langchain_core.output_parsers import StrOutputParser

# --- Setup: This would be done once to build the knowledge base ---

# 1. Load documents (maintenance logs, equipment manuals, etc.)

# loader = DirectoryLoader(...)

# docs = loader.load()

# 2. Split documents into chunks

# text_splitter = RecursiveCharacterTextSplitter(...)

# chunks = text_splitter.split_documents(docs)

# 3. Create a vector store using embeddings.

# Here we use Ollama for local embeddings, but could be OpenAI, Cohere, etc.

# vectorstore = Chroma.from_documents(documents=chunks, embedding=OllamaEmbeddings(model="mistral"))

# retriever = vectorstore.as_retriever()

# For this example, we'll simulate a pre-built retriever

class SimulatedRetriever:

def get_relevant_documents(self, query):

# In a real system, this performs a vector search

print(f"---> Searching for documents related to: '{query}'")

return [

{"page_content": "Log 2024-10-26 03:15: EUV_Tool_05: Plasma instability detected. Pressure fluctuated by 5% over 10s. Operator noted unusual spectral readings."},

{"page_content": "Manual Section 4.2b: Plasma instability in the EUV chamber is often caused by helium coolant contamination or a failing RF generator."}

]

retriever = SimulatedRetriever()

# --- RAG Chain Implementation ---

# This is where the magic happens, combining retrieval with generation

template = """

Answer the question based only on the following context. If you don't know the answer, just say that you don't know.

Context:

{context}

Question: {question}

"""

prompt = ChatPromptTemplate.from_template(template)

# Using a local model via Ollama, reflecting trends in on-prem deployment

# This is a key part of the latest Mistral AI News and LlamaFactory News

llm = Ollama(model="mistral")

rag_chain = (

{"context": retriever.get_relevant_documents, "question": RunnablePassthrough()}

| prompt

| llm

| StrOutputParser()

)

# --- Querying the System ---

query = "What could have caused the recent yield drop on EUV tool 5?"

response = rag_chain.invoke(query)

print("\n--- AI Fab Assistant Response ---")

print(response)This “Fab Assistant” creates a powerful software moat. The value isn’t just in the AI model (e.g., from Mistral AI or Cohere News) but in the entire system, deeply integrated with the manufacturer’s proprietary data and processes. It’s a knowledge asset that competitors cannot easily replicate.

Section 3: Advanced Frontiers – Digital Twins and Reinforcement Learning

The ultimate goal is to create a fully autonomous, self-optimizing fab. This requires moving from prediction to control, a domain where digital twins and reinforcement learning (RL) are the state of the art. This area is heavily influenced by research from labs like Meta AI News and the platforms being built by NVIDIA AI News with their Omniverse.

Digital Twins for Fab Simulation

A digital twin is a high-fidelity virtual simulation of the entire fabrication plant. It’s fed with real-time data from the physical fab, allowing it to mirror the real world’s state. Within this simulation, engineers can:

- Test New Recipes: Experiment with new process parameters without risking expensive wafers.

- Simulate Failures: Understand the cascading effects of a potential equipment failure.

- Train AI Agents: Use the simulation as a training ground for reinforcement learning agents.

Optimizing Processes with Reinforcement Learning

An RL agent can be trained within the digital twin to optimize a complex process, like chemical-mechanical polishing (CMP). The agent’s “actions” are the process parameters (e.g., pressure, rotation speed), the “state” is the current condition of the wafer, and the “reward” is based on the resulting wafer uniformity and yield.

Here is a simplified Python code snippet illustrating the concept of an RL environment for a manufacturing task using the `gymnasium` library, a popular choice in the RL community.

import gymnasium as gym

from gymnasium import spaces

import numpy as np

class FabProcessEnv(gym.Env):

"""

A simplified reinforcement learning environment for optimizing a

single manufacturing process parameter (e.g., deposition time).

"""

def __init__(self):

super(FabProcessEnv, self).__init__()

# Action: Adjust deposition time (+/- seconds)

self.action_space = spaces.Discrete(3) # 0: decrease, 1: maintain, 2: increase

# Observation: Current layer thickness (in nanometers)

self.observation_space = spaces.Box(low=0, high=100, shape=(1,), dtype=np.float32)

# Target thickness for optimal yield

self.target_thickness = 50.0

self.tolerance = 2.0

def _get_obs(self):

return np.array([self.current_thickness], dtype=np.float32)

def reset(self, seed=None, options=None):

super().reset(seed=seed)

# Start with a random thickness to simulate process variability

self.current_thickness = np.random.uniform(40, 60)

return self._get_obs(), {}

def step(self, action):

if action == 0:

self.current_thickness -= 0.5

elif action == 2:

self.current_thickness += 0.5

# Action 1 does nothing

# Add some random process noise

self.current_thickness += np.random.normal(0, 0.1)

# Calculate reward

error = abs(self.current_thickness - self.target_thickness)

terminated = error > 10 # Terminate if process goes way out of spec

if error <= self.tolerance:

reward = 10.0 # High reward for being within tolerance

else:

reward = -error # Negative reward proportional to the error

return self._get_obs(), reward, terminated, False, {}

# --- Using the environment ---

env = FabProcessEnv()

obs, info = env.reset()

print(f"Initial thickness: {obs[0]:.2f} nm")

# Simulate a few steps with random actions

for i in range(5):

action = env.action_space.sample() # An RL agent would choose this action

obs, reward, terminated, _, _ = env.step(action)

print(f"Step {i+1}: Action={action}, New Thickness={obs[0]:.2f}, Reward={reward:.2f}")

if terminated:

print("Process out of spec, resetting.")

obs, info = env.reset()

env.close()By running millions of these simulations, an RL agent can discover a control policy far more optimal than one designed by humans. Deploying this requires extremely robust infrastructure, often managed by platforms like AWS SageMaker or Azure Machine Learning, and served via high-performance engines like the Triton Inference Server News.

Section 4: Best Practices and Strategic Implications

Integrating AI at this scale is not just a technical challenge; it requires a strategic organizational shift. Success hinges on several best practices and an understanding of the broader competitive landscape.

Best Practices for Industrial AI

- Data First: The mantra “garbage in, garbage out” is paramount. Establishing robust data governance, cleaning, and labeling pipelines is the most critical first step.

- Human-in-the-Loop: These AI systems should be designed to augment, not replace, experienced process engineers. Tools like Gradio News or Streamlit News can be used to build simple interfaces for engineers to interact with and validate model outputs.

- Robust MLOps: A model that works in a Google Colab News notebook will fail in a 24/7 production fab. A rigorous MLOps culture, using tools from the ClearML News or Comet ML News ecosystems, is essential for versioning, monitoring, and retraining models.

- Start Small: Instead of attempting to build a full digital twin from day one, focus on a high-value, well-defined problem like a single defect classification or predictive maintenance for one tool.

The New Competitive Moat and Tech Sovereignty

The strategic implications of this AI-hardware fusion are immense. An advanced hardware manufacturer already has a significant “moat” due to massive capital investment and decades of physical engineering expertise. By layering a proprietary, data-driven AI control system on top, they create a second, even more formidable software moat. This system, trained on their unique operational data, becomes a unique asset that cannot be purchased or easily replicated.

Furthermore, this trend has geopolitical significance. By fostering partnerships between regional hardware and AI champions (e.g., in Europe), nations can build a sovereign, vertically integrated tech stack. This reduces reliance on AI ecosystems and cloud infrastructure from other regions, such as those dominated by US giants and their platforms like Amazon Bedrock News or Vertex AI News. It’s a strategic move to ensure long-term technological independence and competitiveness.

Conclusion: The Dawn of the Intelligent Factory

The convergence of advanced AI and semiconductor manufacturing marks a pivotal moment in industrial technology. We are moving beyond using AI for simple analytics and entering an era of AI-driven process control and optimization. This shift, exemplified by collaborations between AI innovators and deep-tech hardware leaders, promises to shatter existing benchmarks for efficiency and yield in chip fabrication. The core takeaways are clear: AI is creating a powerful new software moat within the established hardware moat of advanced manufacturing; the implementation requires a sophisticated, multimodal data strategy; and the geopolitical implications related to tech sovereignty are profound. For engineers, developers, and technology leaders, the message is clear: the future of manufacturing isn’t just about better machines, but about the intelligence that runs them. The next wave of innovation will be led by those who can master this complex and powerful synthesis of silicon and software.